The power take-off driveshaft’s length adjustment is accomplished with square/rectangular shafting, splined shafts, or a profile tubing that has a larger and smaller tube of various shapes that transmit the torque while being able to change length. The length compensation of the PTO shaft must be done with the least amount of thrust pressure as possible.

If too much effort is required for the driveshaft to slide under load, damage is done to the other components of the driveshaft as well as the tractor PTO or implement’s gear box or bearings.

This low effort of movement is especially important on constant velocity drive shafts as too much friction between the sliding members will damage the CV joint itself. Splined shafting or profile tubing that has a low friction coating on one of the pieces will often be used.

Power Take-Off Shaft Tubing Types:

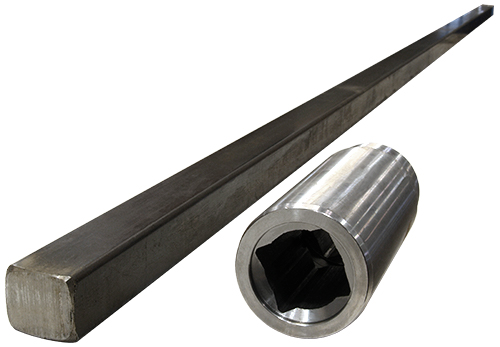

- Square and rectangular shafting will mate with a hollow square or rectangular tube, or a sleeve that has the square or rectangular bore in it and welds to round tube.

- Splined shaft with a splined sleeve welding into round tube, are used in cv applications where low friction length compensation is required, as well as dirty environments where the dirt may do damage to the profile tube design.

- Lemon profile tube is used for both standard and constant velocity drivelines.

- Triangular profile tube is used for both standard and constant velocity drivelines.

- Star shaped profile tubes are popular for their strength and multiple contact faces.

- Bondioli’s 4 lobe profile tube are used in standard and constant velocity PTO drivelines.

- Eurocardan’s York profile tube creates a strong and durable design length compensation.